Requirements

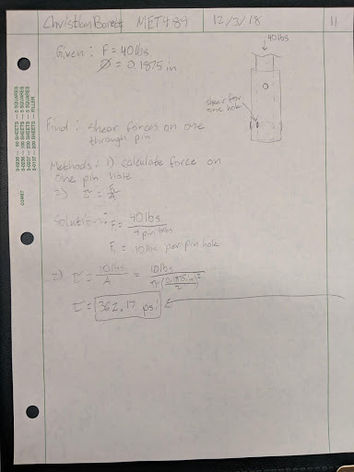

One requirement of this probe is for the probe head to be able to rotate about the X and Y axis 100 degrees. Another Requirement is the probe head must be able to withstand a force of 40 pounds due to the vertical pressure that is expended by the ultrasound technician.

Analysis

One analysis that is crucial to the success of the device is shown in Appendix A-2 and A-3. This analysis focuses on the amount of force that the motors must overcome to move the probe head from a total horizontal position to a vertical position. The amount of stress is greatest when the probe head is horizontal. In analysis A-2, arbitrary numbers were used to get a close answer. In analysis A-3, the design and measurements on the probe was locked down and a final force that the cable must be able to overcome was around 242.8 pounds. The 242.8 pounds was then used to find the torque needed from the motors.

Analysis A-6 explands on the force needed to move the cables when the probe is under load. The radius of the motor shaft was used to find the torque requirements of the motor. The torque requirement calculated was 38.22 lb-in. A motor was found that is rated at 43.4 lb-in, which according to the analysis, the motor will work in the system.